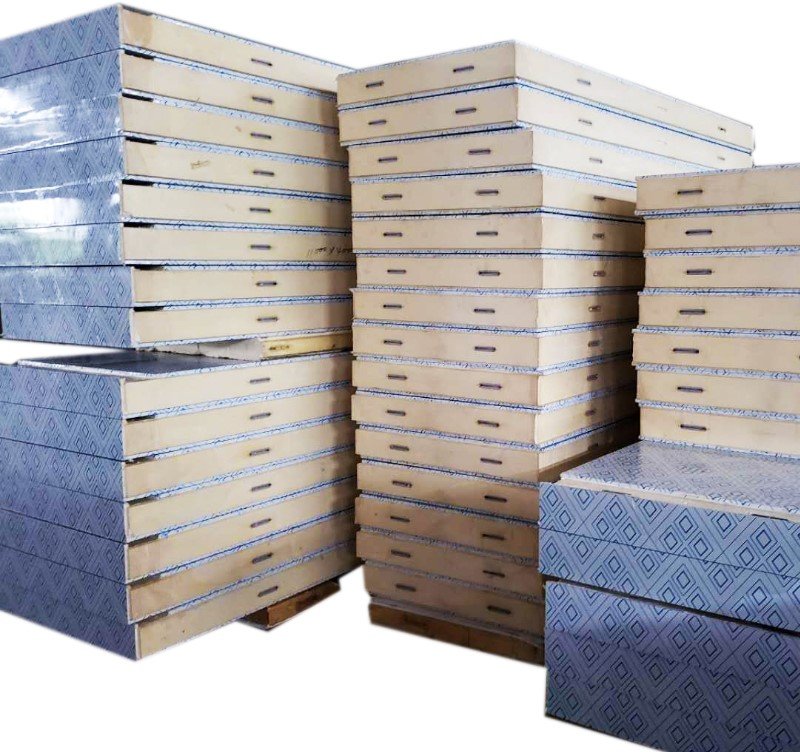

Connection mode of cold storage panel:

◇ The cold storage panel adopts inlaid eccentric hook (PU material hook and all metal hook) concave convex groove connection to realize the cold bridge breaking. The joint of the cold storage panel shall be tight, and the hole cap shall be installed.

1. Introduction to cold storage panel parameters:

① The standard width is 960mm, and other sizes can be customized. The standard cold storage panel at the corner is 480 * 480mm, and 12.15m cold storage plate can be made.

② Thickness of cold storage panel: δ50mm, δ75mm, δ100mm, δ120mm, δ150mm, δ200mm

③ Material of cold storage panel: customizable (color steel, 201# or 304# stainless steel, embossed aluminum plate, anti-skid aluminum plate, patterned iron plate, galvanized plate, etc.)

2. Cold storage panel insulation material and feeding density:

The rigid polyurethane (PU) process is formed by high-pressure foaming and lamination. The executive standard JB / t6527-2006 is 38-60kg / m3 (the common feeding density is 40, 42 and 45kg / m3), and the thermal conductivity is ≤ 0.024w/m • K.

3. Features of polyurethane cold storage panel:

① The concave convex groove structure of cold storage panel improves the insulation and air tightness at the joint of the panel, and the installation is more convenient;

② The cold storage panel is uniform and stable with good heat insulation performance;

③ Light weight and generous appearance, which can effectively solve the temperature difference of refrigeration industry;

④ The size of the cold storage body can be changed freely in the three directions of length, width and height, which can be expanded or reduced as needed. The assembly board can also be disassembled and reassembled in different places, which is simple and fast to install.

⑤ Polyurethane foam has the characteristics of environmental protection, anti-corrosion, flame retardant (self extinguishing after leaving the fire), moisture prevention, good thermal insulation and so on.

⑥ Advanced equipment is adopted for foaming, with uniform foam quality and general standard of bulk density of 40 ± 2kg / m3.

Technical parameters:

① Motor: 380V, 50Hz, 0.4KW, 1380 rpm

② Reducer: 2m, 50:1

③ Pitch of rotating chain (sleeve runner chain): 12.7mm, roller diameter: 8.5mm

④ Closing speed: 0.2m/s

⑤ Electric heater voltage 36V, power double fan 240W

⑥ Applicable temperature of door leaf: – 40 ℃ ~ normal temperature

Automatic electric sliding door is a kind of sliding cold room door, which can recognize the action of people approaching the door as the control unit of door opening signal, open the door through the driving system, automatically close the door after leaving, and control the opening and closing process.

Product summary: the electric sliding door has the characteristics of beautiful and novel shape, compact and advanced structure, simple operation, firmness and durability, strong rigidity, good sealing, no floor area, flexible and convenient opening and closing, wind prevention, dust prevention, fire prevention, theft prevention and so on. Electric and infrared induction. In case of abnormal power failure, it can be opened manually, and the motor has self-protection function. It can be opened in both directions and in one direction.

Scope of application: it is applicable to civil engineering warehouse with warehouse temperature not lower than – 30 ℃ and assembled fresh-keeping warehouse, cold storage, freezing warehouse, etc. When the temperature difference inside and outside the warehouse is greater than 50 ℃ and the relative humidity is greater than 80%, it can play a good heat insulation and sealing effect.

Type specification

According to the specific requirements of various cold storages, according to the size of the door opening, it can be divided into two models and 10 specifications, or special specifications and sizes can be designed and produced separately according to the needs of users

Model I | 900×2000 | 1200×2000 | 1200×2500 | 1500×2200 | 1500×2500 |

Model 2 | 1600×2200 | 1600×2500 | 1800×2500 | 1600×2700 | 1800×2700 |

Manual sliding door is generally used in civil cold storage and cold storage with a temperature of no less than minus 40 degrees. It is generally used in ordinary cold storage, freezer, marine cold storage and constant temperature workshop. The scope of use of manual sliding door is still relatively wide, but it is mostly used in small cold storage. Manual sliding door can play a good heat insulation and sealing effect for cold storage with a temperature difference of more than 50 degrees Celsius and a relative humidity of more than 80%.

Introduction: the door leaf of the cold room door is generally injected with polyurethane pressure injection machine for one-time foaming molding. The polyurethane tissue is dense, evenly filled everywhere in the door, there is no shrinkage phenomenon, and the door surface is flat and beautiful.

Features: simple structure, beautiful appearance, good sealing and heat insulation. At the same time, it has the characteristics of safe and practical escape safety device in the warehouse.

Specification: single or double sliding doors can be customized, the door opening direction can be customized, the door opening size can be customized, and the surface material can be color steel or stainless steel

◇ It can be opened in double or single, and door opening size can be selected.

◇ It can be equipped with polyurethane integral foaming small door, and double-layer hollow toughened glass can be selected for visual window perspective.

◇ Application: widely used in food, industry, supermarket, storage and other fresh-keeping, cold storage and quick freezing.

◇ Features: the door panel can be opened and closed automatically, which is convenient and labor-saving, and has good heat insulation performance.

The characteristic of fully buried cold room door is that the door body is flat with the door frame, which can automatically close and compress, with beautiful appearance, good sealing and heat insulation.

After the door leaf of the hinge door is opened, it can return automatically, and the appearance of the storage body is simple. There is an escape handle inside the library.

The position of the hinge is proportional to the height and width of the door. The appropriate position can ensure the free and stable opening of the door. It is generally known that the height and width of the door can determine the position of the hinge.

Applicable temperature: -35 ℃ ~+65 ℃

Door panel manufacturing: It is manufactured by special film pressing process. The inner insulation material is cast and formed by polyurethane. The thickness is generally 75mm and 100mm. The embedded rubber sealing strip can be easily assembled and replaced.

Door frame: Prefabricated PVC shaped door frame, and heating wire groove is reserved in the door frame

Panel material selection: Color steel plate, stainless steel plate, the surface is covered with protective film, and other types of panels can be customized

Accessories: Optional imported door lock, beautiful, practical and reliable

Product performance of cold storage hinged door:

① The hinged door of cold storage is suitable for small cold storage;

② It can be used as PVC door frame or color coated steel plate or stainless steel plate; The door frame of the cold storage is made of aluminum-plastic composite material, with cold bridge design and good load-bearing capacity. The PVC shaped door frame is prefabricated, and the groove with electric heating wire is reserved in the door frame;

③ Rubber sealing strip is adopted for good thermal insulation;

The integrated bending process is adopted, with beautiful appearance.

Half-buried hinged cold room door is manufactured by special film pressing process. The inner insulation material is cast and formed by polyurethane. The thickness is generally 75mm and 100mm. Other specifications are customized. The embedded rubber sealing strip can be easily assembled and replaced.

Applicable temperature: -35 ℃ ~+65 ℃

Door panel manufacturing: It is manufactured by special film pressing process. The inner insulation material is cast and formed by polyurethane. The thickness is generally 75mm and 100mm. The embedded rubber sealing strip can be easily assembled and replaced.

Door frame: Prefabricated PVC shaped door frame, and heating wire groove is reserved in the door frame

Panel material selection: Color steel plate, stainless steel plate, the surface is covered with protective film, and other types of panels can be customized

Accessories: Optional imported door lock, beautiful, practical and reliable

Specification of double opening half-buried door (other different sizes can be customized)

Model | Door Opening Size | Door Panel Size |

EFC1220 | 1200*2000 | 1290*2900 |

EFC1524 | 1500*2400 | 1590*2490 |

EFC1826 | 1800*2600 | 1890*2690 |

Product features

◇ Appearance: Double galvanized steel plate with polyurethane layer, surface embossing design, easy to clean;

◇ Wind resistance: with external stiffeners tested by European standards;

◇ Air tightness: the top, bottom and both sides of the door panel are equipped with high-quality rubber sealing strips;

◇ Safety device: anti falling device, airbag (optional), anti wire rope breaking device and torsion spring breaking safety device.

The vertical lifting cold room door is an industrial door used in the industrial plant, which corresponds to the sliding door, industrial sliding door and wind resistant rolling shutter door. The lifting door is commonly used in the plant gate because of its high sealing performance and safety performance.

Product overview: industrial doors are common facilities for enterprises. They are suitable for large warehouses, logistics industries, medicine, food, factories and mining enterprises and other industries with high requirements for opening speed, thermal insulation, sound insulation, sealing, wind resistance and so on. Especially where the door opening is large and it is inconvenient to install the ground door body, it plays a convenient and fast opening role.

Principle: the industrial sliding door is composed of a series of door panels and rises along the track. The torsion spring system or counterweight system ensures the balance of the door body. The installation track is close to the inside of the building as much as possible, which can save a lot of internal space of the building. The lifting door can be designed into different installation methods according to the size and shape of your building. The selection of door lifting mode can be based on the following basic conditions: door opening size; Upper space of door opening; Side space of door opening; Door opening depth.

According to the actual situation of the building site and the owner’s requirements for the use of space, the following lifting methods can be realized to meet the requirements of rational use of space to the greatest extent.

① Standard lifting: applicable to door top space: within 200-300mm;

② High lift: applicable to the door top space: >300mm< door opening height

③ Vertical lifting: applicable to door top space: > or = door opening height

④ Inclined roof lifting: it is applicable to the slope shape of the door ceiling, and the track is parallel to the ceiling.

Standard ceiling industrial air cooler is a kind of cooling equipment widely applied to various of refrigeration storage, such as quick frozen food, fresh keepingm etc.There are three types available: DL, DD and DJ. DL type is suitable for fresh-keeping storehouse around 0 degree, DD type is suitable for cold storage around-18 degree, DJ type is suitable for quick frozen storage around -25 degree.The features as follows.

◆ Reasonable structure, uniform frosting, high efficiency heat exchange

◆ The shell is made of quality steel, excellent corrosion resistance, good look

◆ Assembled with quality fan motor, with low noise,big air volume, and stable operation

◆ U-shaped stainless tube to make sure quick defrosting

◆ There are different options for the shell materials according to customer’s requirement

◆ With high gas tightness

Ceiling type double side wind blown industrial air cooler is most suitable for food process workshop, also widely used in supermarket and hotel. They are with reasonable structure, less frosting, low noiseand extures high efficiency heat exchange.

◆ The shell is made of quality steel plate, excellent corrosion resistance, good look

◆ Assembled with axial fan motor, double side wind blown, low noise

◆ U-shaped stainless tube to make sure quick defrosting

◆ Customizable

Products features:

Water-defrosting industrial air-cooler is one kind of cooling equipment used in those cold storages wher electrical defrosting is not applicable, or quick defrosting is required. According to applicable temperature there are 3 series industrial air cooler including DL DD DJ, which are applicable to aborut 0℃, -18℃ and -25℃ cold storages respectively.

This series industrial air cooler features as follows:

● The shell is made of quality steel plate; plastic-sprayed surface is anti-corrosive, and its appearance is beautiful.

● Coiled pipes are mechanical expanding tubes in saggered arrangement; therefore, copper tubes and fins are com-bined closely and ensure good effect of heat exchange.

● Water defrosting realizes quick defrosting, good effect and less energy consumption.

● Long-distance air supply or explosion-proof motors can be used according to customers requirements.

Products features:

Water-defrosting industrial air-cooler is one kind of cooling equipment used in those cold storages where electrical defrosting is not applicable, or quick defrosting is required. According to applicable temperature there are 3 series industrial air cooler including DL DD DJ, which are applicable to aborut 0℃, -18℃ and -25℃ cold storages respectively.

This series industrial air cooler features as follows:

● The shell is made of quality steel plate; plastic-sprayed surface is anti-corrosive, and its appearance is beautiful.

● Coiled pipes are mechanical expanding tubes in saggered arrangement; therefore, copper tubes and fins are com-bined closely and ensure good effect of heat exchange.

● Water defrosting realizes quick defrosting, good effect and less energy consumption.

● Long-distance air supply or explosion-proof motors can be used according to customers requirements.

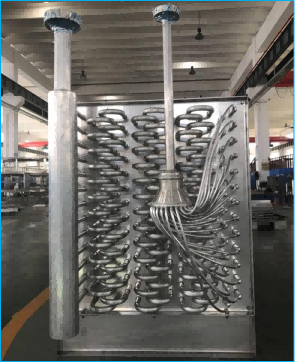

(1) The evaporation tube and fins of the evaporator are all made of SUS304. The liquid supply and heat exchange methods are advanced and efficient. The evaporation tube is φ25×2.2, the fin thickness is 0.4mm, and the high flanging is 10-12mm. Stainless steel outer frame, withstand voltage test ≥24kg/cm2, efficiency is 30% higher than ordinary evaporator.

(2) The evaporator adopts a variable fin pitch design, the fin pitch at the air inlet is 20mm, and the fin pitch at the outlet is 10mm. This variable fin pitch structure ensures uniform and slow frosting on the evaporator, extending the continuity of the quick-freezer operating hours.

(3) The evaporator is equipped with a large-capacity water flushing device. Normal temperature water is usually used for defrosting when the evaporator is stopped. The normal temperature water is introduced into the upper end of the evaporator and flows down evenly from gravity through the uniformly distributed small holes of the water tray to melt the frost condensed on the surface of the fins. Fast and thorough.

(1) The evaporation tube and fins of the evaporator are all made of rust-proof aluminum alloy. The liquid supply and heat exchange methods are advanced and efficient. The evaporation tube is φ25×2.2, the fin thickness is 0.4mm, and the high flanging is 10-12mm. Stainless steel outer frame, withstand voltage test ≥24kg/cm2, efficiency is 30% higher than ordinary evaporator.

(2) The evaporator adopts a variable fin pitch design, the fin pitch at the air inlet is 20mm, and the fin pitch at the outlet is 10mm. This variable fin pitch structure ensures uniform and slow frosting on the evaporator, extending the continuity of the quick-freezer operating hours.

(3) The evaporator is equipped with a large-capacity water flushing device. Normal temperature water is usually used for defrosting when the evaporator is stopped. The normal temperature water is introduced into the upper end of the evaporator and flows down evenly from gravity through the uniformly distributed small holes of the water tray to melt the frost condensed on the surface of the fins. Fast and thorough.

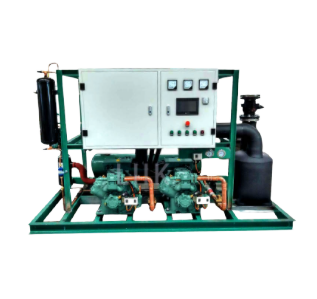

Advantages:

All core components are imported brands

Compressor: Hanbell, Taiwan

Solenoid valve: Danfoss, Denmark

Expansion valve: Emerson

Safety valve: Castel, Italy

Electrical components: Schneider Schneider, France

Application:

It is mainly used in the cold storage of food / pharmaceutical industry to provide low-temperature cold source for freezing storage and quick freezing storage. At the same time, this model is widely used in the ammonia to fluorine market (ammonia to fluorine sharp tool)

System characteristics:

The two-stage compressor has ultra-high operation efficiency, and the average energy saving is more than 30% compared with the single-stage unit;

R404A or R507A refrigerant is adopted, and the temperature reaches – 60 ℃;

Oil separation system;

The differential pressure regulating valve is used to ensure the two-stage oil supply of the compressor and normal lubrication and cooling;

Comprehensive and reliable unit safe operation protection function;

Built in motor temperature detection sensor to ensure the safe operation of the motor;

Humanized human-computer interaction interface makes user operation easier;

Advanced PLC programmable control, supplemented by high-precision sensors, realizes the automatic and accurate adjustment of unit load, reduces energy consumption, and truly realizes unmanned intelligent management.

Application:

Quick freezing, freezing, refrigeration, preservation, air conditioning, food, medicine, industry, chemical industry and other special needs warehouses

Advantages:

1. Parallel units are equipped with energy regulation. Through the combination of multiple compressors, multi-level energy regulation stages can be provided to realize the best energy regulation for load change, improve efficiency and save energy; According to different refrigeration systems, it can be adjusted automatically, which is 30% 60% higher than that of single unit

2. The packed pipeline design minimizes the pressure loss of the pipeline and maximizes the efficiency of the unit

3. Provide multi suction branch control. According to the needs, one unit can supply multiple evaporation temperatures, and effectively use the cooling capacity of each evaporation temperature to make the system operate under the most energy-saving working condition

4. The highly integrated design concept reduces the consumption of pipelines and cables and shortens the construction cycle

5. It adopts high-quality German Bitzer bizel compressor and high-quality imported control valve parts

We will contact you within 12 hours, please pay attention to the email with the suffix “@efcwork.com”.